DEFECT DETECTION IN CARBON FIBER REINFORCED POLYMER USING PEARSON CORRELATION COEFFICIENT FROM ULTRASONIC ECHO SIGNALS

Abstract

Carbon fiber reinforced polymer (CFRP) is a composite material widely used in the aerospace, automotive, and marine industries due to its high strength and low weight. However, the reliability of CFRP can be compromised by internal defects occurring during manufacturing or use. This study aims to detect defects in CFRP using the Pearson correlation coefficient from ultrasonic echo signals. This method utilizes ultrasonic waves to identify defects based on changes in signal patterns. The reference signal is obtained by averaging the signals from several defect-free locations. Variations in the measurement signals compared to the reference signal are quantified using the Pearson correlation coefficient to classify defect-free and defect-containing areas. The test samples consisted of thin CFRP plates with artificial defects created using Teflon material in the form of circles with a radius of 15 mm, placed at two different depths. The results indicate that the Pearson correlation coefficient effectively distinguishes between defect-free and defective areas. Defect-free areas showed correlation values in the range of 0.97 to 1, while defective areas showed low correlation values in the range of 0 to 0.36.

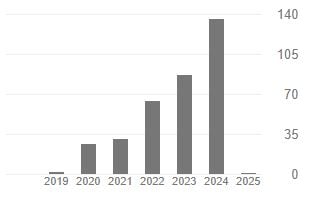

Downloads

References

S. Hegde, B. Satish Shenoy, and K. N. Chethan, “Review on carbon fiber reinforced polymer (CFRP) and their mechanical performance,” Mater Today Proc, vol. 19, pp. 658–662, 2019, doi: 10.1016/j.matpr.2019.07.749.

D. K. Rajak, P. H. Wagh, and E. Linul, “Manufacturing Technologies of Carbon/Glass Fiber-Reinforced Polymer Composites and Their Properties: A Review,” Polymers (Basel), vol. 13, no. 21, p. 3721, Oct. 2021, doi: 10.3390/polym13213721.

R. Bintarto, Moch. Syamsul Ma’arif, F. Gayuh Utami Dewi, S. Sugiarto, N. Hamidi, and P. Heryana, “Pengaruh Daya Pemanasan Microwave Oven Terhadap Kekuatan Tarik Komposit Serat Daun Nanas Bermatrik Epoxy,” Scientific Journal of Mechanical Engineering Kinematika, vol. 6, no. 2, pp. 182–193, Dec. 2021, doi: 10.20527/sjmekinematika.v6i2.207.

A. Zarei, S. Farahani, and S. Pilla, “An experimental study on the manufacturing of engineered defects in composite plates,” Composites Part C: Open Access, vol. 9, p. 100327, Oct. 2022, doi: 10.1016/j.jcomc.2022.100327.

J. Chen, Z. Yu, and H. Jin, “Nondestructive testing and evaluation techniques of defects in fiber-reinforced polymer composites: A review,” Front Mater, vol. 9, Oct. 2022, doi: 10.3389/fmats.2022.986645.

B. Wang, P. He, Y. Kang, J. Jia, X. Liu, and N. Li, “Ultrasonic Testing of Carbon Fiber-Reinforced Polymer Composites,” J Sens, vol. 2022, pp. 1–20, Jun. 2022, doi: 10.1155/2022/5462237.

J. Jodhani, A. Handa, A. Gautam, Ashwni, and R. Rana, “Ultrasonic non-destructive evaluation of composites: A review,” Mater Today Proc, vol. 78, pp. 627–632, Jan. 2023, doi: 10.1016/j.matpr.2022.12.055.

M. Ma et al., “High Precision Detection Method for Delamination Defects in Carbon Fiber Composite Laminates Based on Ultrasonic Technique and Signal Correlation Algorithm,” Materials, vol. 13, no. 17, p. 3840, Aug. 2020, doi: 10.3390/ma13173840.

W. Zeng et al., “Research on a laser ultrasonic visualization detection method for human skin tumors based on pearson correlation coefficient,” Opt Laser Technol, vol. 141, p. 107117, Sep. 2021, doi: 10.1016/j.optlastec.2021.107117.

Y. Chang, D. Yang, and Y. Guo, “Laser ultrasonic damage detection in coating-substrate structure via Pearson correlation coefficient,” Surf Coat Technol, vol. 353, pp. 339–345, Nov. 2018, doi: 10.1016/j.surfcoat.2018.09.005.

D. Mulyadi, B. Sofiyanti, A. Adhi Nugroho, P. Studi Teknik Mesin, and U. Buana Perjuangan Karawang, “Optimasi Parameter Mesin Ultrasonic Welding Untuk Penyambungan Material Termoplastik,” Scientific Journal of Mechanical Engineering Kinematika, vol. 9, no. 1, pp. 55–65, 2024, doi: 10.20527/sjmekinematika.v9i1.296.

V. Yudha, Ferriawan Yudhanto, and Joko Waluyo, “Analisa Sifat Fisis dan Mekanis Komposit Hibrid Serat Jute/Karbon yang Dibuat dengan Metode Vacuum Infusion sebagai Alternatif Bahan Helm,” Scientific Journal of Mechanical Engineering Kinematika, vol. 8, no. 1, pp. 25–35, Jun. 2023, doi: 10.20527/sjmekinematika.v8i1.248.

M. E. Ibrahim, “Ultrasonic inspection of hybrid polymer matrix composites,” Compos Sci Technol, vol. 208, p. 108755, May 2021, doi: 10.1016/j.compscitech.2021.108755.

I. Papa, V. Lopresto, and A. Langella, “Ultrasonic inspection of composites materials: Application to detect impact damage,” International Journal of Lightweight Materials and Manufacture, vol. 4, no. 1, pp. 37–42, Mar. 2021, doi: 10.1016/j.ijlmm.2020.04.002.

L. Jonveaux, “un0rick : open-source fpga board for single element ultrasound imaging,” 2019. doi: 10.5281/zenodo.3364559.

A. P. Hariyanto, N. T. Budiarti, Suprijanto, K. H. Ng, F. Haryanto, and Endarko, “Evaluation of physical properties and image of polyvinyl chloride as breast tissue equivalence for dual-modality (mammography and ultrasound),” Phys Eng Sci Med, vol. 46, no. 3, pp. 1175–1185, Sep. 2023, doi: 10.1007/s13246-023-01283-y.

H. Susanti, H. Mukhtar, S. Suprijanto, and W. A. Cahyadi, “Initial Study of A-mode Ultrasound Spectroscopy Through Mechanical Wave Scattering Phenomenon for Measuring 3D-printed Bone Model Density,” International Journal of Mechanics, vol. 17, pp. 74–79, Aug. 2023, doi: 10.46300/9104.2023.17.11.

L. Huang, J. Li, and B. Li, “Experimental research on ultrasonic A-scan testing technology of composite solid propellant,” J Phys Conf Ser, vol. 2338, no. 1, p. 012011, Sep. 2022, doi: 10.1088/1742-6596/2338/1/012011.

A. R. Ramzi, M. F. Mahmod, and A. B. Elmi, “Immersion ultrasonic inspection system for small scaled composite specimen,” ARPN Journal of Engineering and Applied Sciences, vol. 10, no. 22, Dec. 2015.

Copyright (c) 2024 Authors

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.