EFFECT OF WIRE ARC ADDITIVE MANUFACTURING (WAAM) PROCESS PARAMETERS ON THE GEOMETRY OF SINGLE ER5356 WELD BEADS

Abstract

This study examined the effects of WAAM printing parameters on single weld bead geometry using ER5356 aluminum electrode (0.1 mm diameter). Parameters varied include Voltage (18 V, 22 V, 26 V), Current (100 A, 140 A, 180 A), and Feedrate (500 mm/min, 750 mm/min, 1000 mm/min). The process produced both discontinuous and continuous weld beads. Continuous weld beads with Heat Input (HI) ranging from 0.17 kJ/mm to 0.43 kJ/mm were achieved under low voltage (18 V) and high current (180 A) settings. Voltage variation did not significantly affect bead consistency, but consistent welds were more prevalent under high-current and low-voltage conditions than with high-voltage settings. Feedrate influenced bead geometry, with lower feedrates producing larger weld grains. The smallest layer width (6.77 mm) and height (1.36 mm) were obtained with 22 V, 140 A, and 1000 mm/min, while the largest width (14.29 mm) and height (2.8 mm) resulted from 26 V, 180 A, and 500 mm/min. This study highlights the impact of voltage, current, and feedrate on weld bead geometry and consistency in WAAM processes.

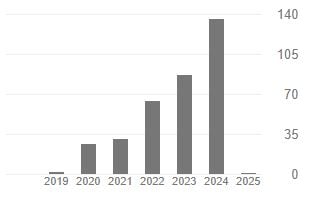

Downloads

References

R. Huang et al., “Energy and emissions saving potential of additive manufacturing: the case of lightweight aircraft components,” J. Clean. Prod., vol. 135, pp. 1559–1570, 2016, doi: 10.1016/j.jclepro.2015.04.109.

J. Aldo and R. S. Rahmany, “Analisis Pengaruh Temperatur Media Pendingin Proses Pengelasan Smaw Terhadap Nilai Kekerasan Dan Pada Baja Karbon Sedang,” Sci. J. Mech. Eng. Kinemat., vol. 7, no. 2, pp. 73–82, 2022, doi: 10.20527/sjmekinematika.v7i2.226.

D. Mulyadi, B. Sofiyanti, A. Adhi Nugroho, P. Studi Teknik Mesin, and U. Buana Perjuangan Karawang, “Optimasi Parameter Mesin Ultrasonic Welding Untuk Penyambungan Material Termoplastik,” Sci. J. Mech. Eng. Kinemat., vol. 9, no. 1, pp. 55–65, 2024, doi: 10.20527/sjmekinematika.v9i1.296.

J. B. Bento, A. Lopez, I. Pires, L. Quintino, and T. G. Santos, “Non-destructive testing for wire + arc additive manufacturing of aluminium parts,” Addit. Manuf., vol. 29, no. July, p. 100782, 2019, doi: 10.1016/j.addma.2019.100782.

T. Abe and H. Sasahara, “Layer geometry control for the fabrication of lattice structures by wire and arc additive manufacturing,” Addit. Manuf., vol. 28, no. January, pp. 639–648, 2019, doi: 10.1016/j.addma.2019.06.010.

A. E. Tontowi, Laser Sintering: Teori, Simulasi Numerik dan Eksperimen, 1st ed. Yogyakarta: UGM PRESS, 2018. [Online]. Available: https://books.google.co.id/books?id=L65TDwAAQBAJ&lpg=PA1&ots=1nlwaOMUfN&lr&pg=PA1#v=onepage&q&f=false

J. Xiong, Y. Li, R. Li, and Z. Yin, “Influences of process parameters on surface roughness of multi-layer single-pass thin-walled parts in GMAW-based additive manufacturing,” J. Mater. Process. Technol., vol. 252, pp. 128–136, 2018, doi: 10.1016/j.jmatprotec.2017.09.020.

D. Ding, Z. Pan, D. Cuiuri, and H. Li, “A multi-bead overlapping model for robotic wire and arc additive manufacturing (WAAM),” Robot. Comput. Integr. Manuf., vol. 31, pp. 101–110, 2015, doi: 10.1016/j.rcim.2014.08.008.

J. Wanwan, Z. Chaoqun, J. Shuoya, T. Yingtao, W. Daniel, and L. Wen, “Wire Arc Additive Manufacturing of Stainless Steels: A Review,” Appl. Sci., vol. 10, p. 1563, 2020.

J. Y. Bai, C. L. Yang, S. B. Lin, B. L. Dong, and C. L. Fan, “Mechanical properties of 2219-Al components produced by additive manufacturing with TIG,” Int. J. Adv. Manuf. Technol., vol. 86, no. 1–4, pp. 479–485, 2016, doi: 10.1007/s00170-015-8168-x.

N. Ana Rosli, M. Rizal Alkahari, F. Redza Ramli, S. Mat, A. Anas Yusof, and F. Kejuruteraan Mekanikal, “Influence of process parameters on dimensional accuracy in GMAW based additive manufacturing,” no. August, pp. 7–9, 2019, [Online]. Available: https://www.researchgate.net/publication/342671975

F. Martina, “Investigation of methods to manipulate geometry, microstructure and mechanical properties in titanium large scale Wire+Arc Additive Manufacturing,” Cranf. Univ., 2014, [Online]. Available: http://dspace.lib.cranfield.ac.uk/handle/1826/9270

W. Tayier, S. Janasekaran, and V. P. Vijayasree, “Evaluation of heat input and bead geometry of zincalume steel (G550) welded joint between metal inert gas (MIG) and laser beam welding (LBW),” Mater. Today Proc., vol. 48, pp. 895–904, 2021, doi: 10.1016/j.matpr.2021.02.494.

N. W. Dreveck, L. D. Barbetta, D. Bond, and G. O. Verran, “Influence of push and pull techniques on high-speed buried-arc gmaw process,” Soldag. e Insp., vol. 25, no. September, pp. 1–11, 2020, doi: 10.1590/0104-9224/SI25.23.

X. Lv, X. Sun, K. Qi, and C. Shi, “Establishment of a geometric model for weld beads based on welding parameters,” in Proc.SPIE, Apr. 2024, p. 1308224. doi: 10.1117/12.3026869.

S. Khrais, H. Al Hmoud, A. Abdel Al, and T. Darabseh, “Impact of Gas Metal Arc Welding Parameters on Bead Geometry and Material Distortion of AISI 316L,” J. Manuf. Mater. Process., vol. 7, no. 4, 2023, doi: 10.3390/jmmp7040123.

K. A. G and R. R. V, “Investigation on effects of parameters of GMAW process on bead geometry, hardness and microstructure of AISI 410 steel weldments,” Adv. Mater. Process. Technol., vol. 8, no. 3, pp. 2450–2464, 2022, doi: 10.1080/2374068X.2021.1912537.

V. Pratap Singh, K. Dahiya, and P. Khanna, “Mathematical analysis of effect of process parameters on weld bead geometry of MIG welded low carbon steel plates,” Mater. Today Proc., vol. 56, pp. 655–660, 2022, doi: 10.1016/j.matpr.2022.01.022.

H. Liao et al., “Effects of welding speed on welding process stability, microstructure and mechanical performance of SUS304 welded by local dry underwater pulsed MIG,” J. Manuf. Process., vol. 88, no. September 2022, pp. 84–96, 2023, doi: 10.1016/j.jmapro.2023.01.047.

X. Wu, X. Zhao, J. Chen, Z. Zhang, and C. Wu, “Simulation of the influence of welding parameters on weld pool behavior during a TIG-MIG hybrid welding process,” J. Manuf. Process., vol. 79, no. May, pp. 460–475, 2022, doi: 10.1016/j.jmapro.2022.05.007.

Z. Yin and J. Xiong, “Stereovision measurement of layer geometry in wire and arc additive manufacturing with various stereo matching algorithms,” J. Manuf. Process., vol. 56, no. April, pp. 428–438, 2020, doi: 10.1016/j.jmapro.2020.05.001.

Copyright (c) 2024 Deni Andriyansyah, Herianto, Emanuel Budi Raharjo, Husein Arif Susanto, Gervasius Andro Hermawan Mintardjo

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.